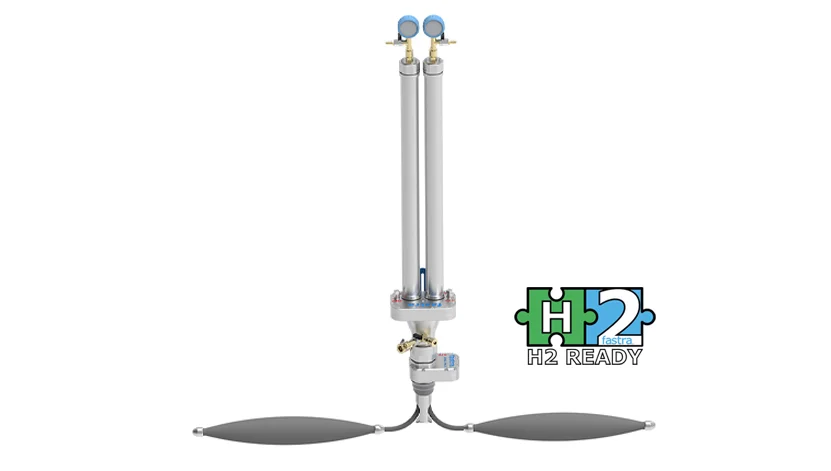

STOPL-S-F1 for steel pipeline

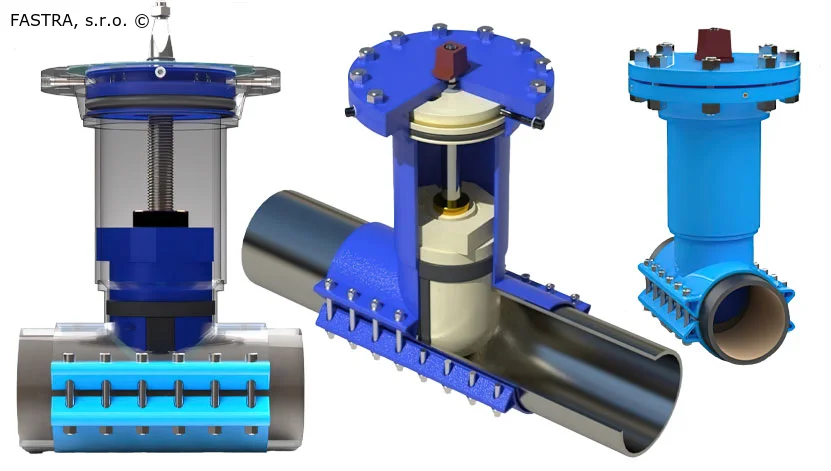

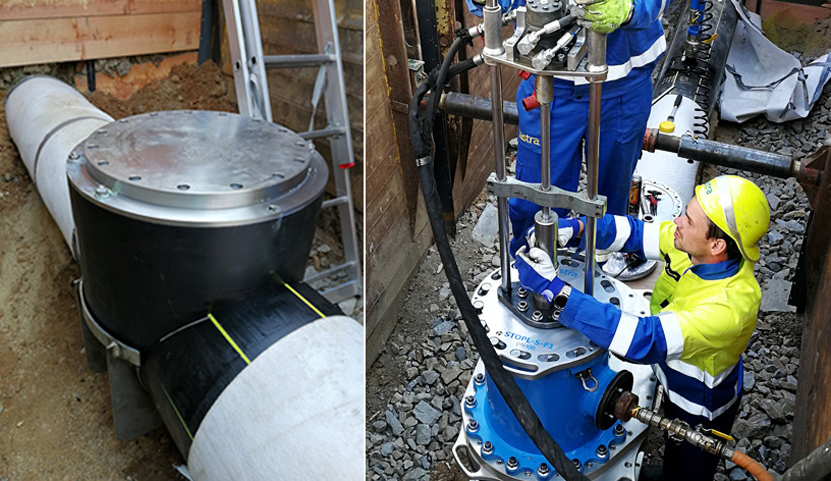

The STOPL-S-F1 device is used to temporarily interrupt the flow of medium in the pipeline with (or without) overpressure without any leakage of the medium. The device works on the principle of inserting a stopling head with a sealing through a hole drilled into the pipeline, moving it outside the drilled hole and then compressing the seal so that the entire cross-section of the pipeline is closed (sealed), thereby interrupting the flow of the medium. The device is connected to the pipeline using a special fitting, perpendicular to the pipeline axis.

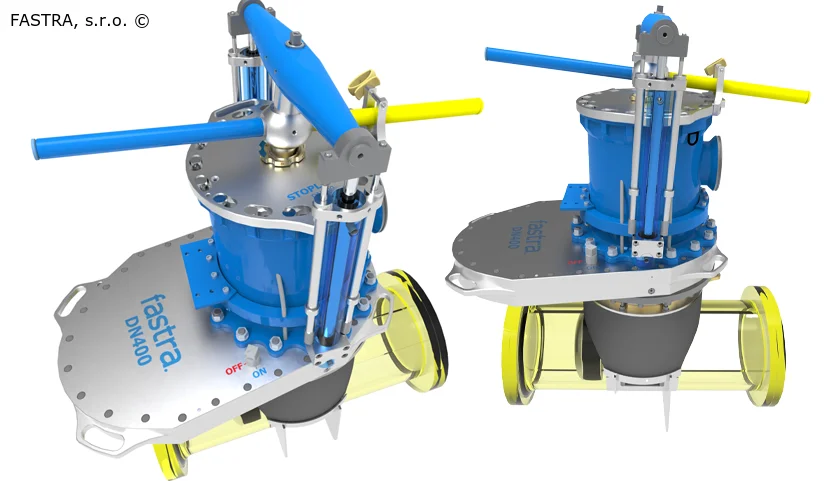

- Fast and simple assembly

- System of replaceable lids

- Bayonet lids

- Considerable shortening of the time between the operations

- High variability

- Increasing of safety

- Simple solution for a bypass

Technical parameters:

Material and diameter of a sealed pipeline: steel pipeline DN65-DN400, PE pipeline dn90 - dn400.

Medium: natural gas, non agressive gas, other medium after consultation with a producer.

Maxim overpresure in a sealed pipeline: up to 8 bar (0,8MPa)

Working temperature: -10/+50 °C