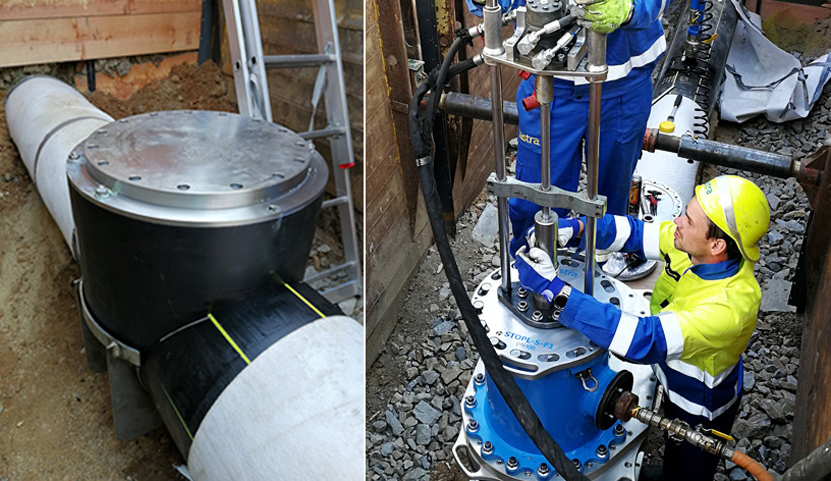

Device STOPL-S-F1 DN 500 for steel pipelines

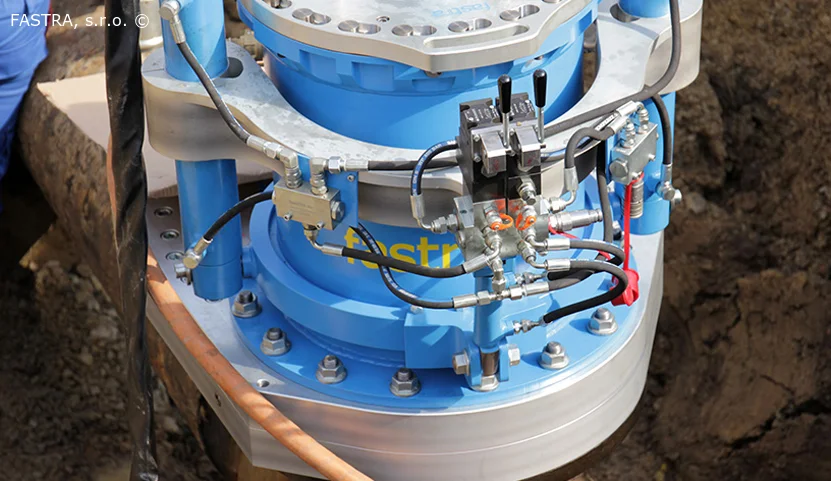

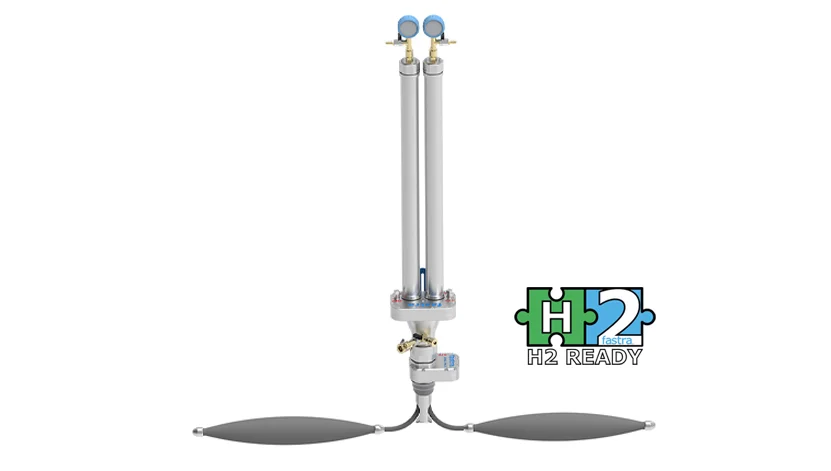

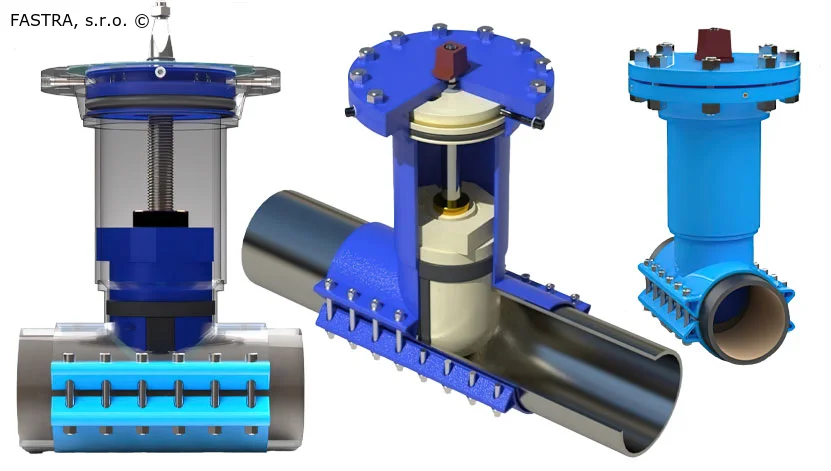

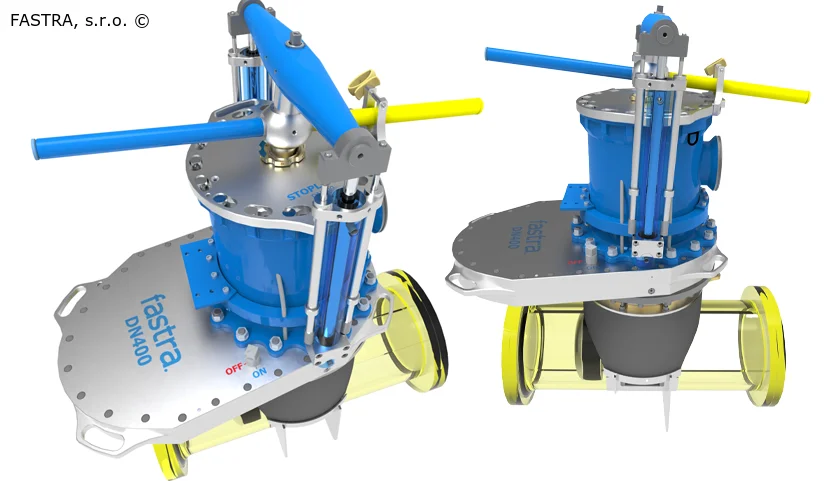

The STOPL-S-F1 DN 500 device shall be used to temporarily interrupt the flow of medium in a pipeline with or without an internal overpressure without medium leakage (also referred to as pipeline Line Stop shut-off). The device relies on the principle of inserting a stopple head fitted with a seal through a drilled hole into the pipeline, moving it beyond the drilled hole and consequently compressing the seal until the entire cross-section of the pipeline is closed. By doing so, the media flow is interrupted. The device is connected perpendicular to the pipeline axis using a custom fitting mounted on the pipeline. A stopple head mounted on a stopple rod is introduced by hydraulic telescopic cylinders connected by crossbars with the stopple rod mounted on them. Tilting the rod so that the stopple head can be positioned outside the drilled hole is also carried out hydraulically. In principle, the device utilises the characteristic features of the STOPL-S-F1 series and offers the following advantages:

- Quick and easy installation

- Interchangeable lid system

- Bayonet-type locking of the loading chamber

- Significant reduction in preparation time for individual technological operations

- High variability

- High level of safety

- Simple by-pass solution

Material and size of the pipeline to be sealed off: Steel pipeline DN 500.

Media: Natural gas, non-aggressive gases, other media after consultation with the manufacturer.

Maximum pressure in the closed-off pipeline: up to 8 bar

Operating temperature: -10/+50°C

Certification

Professional and binding opinion of the TECHNICAL INSPECTORATE OF THE CZECH REPUBLIC (TIČR) on compliance with the safety requirements for dedicated technical equipment - EC Declaration of Conformity with Directive 2014/34/EU of the European Parliament and the Council.