Pipeline Plugging Equipment

Pipeline plugging equipment is used to temporarily stop the media flow inside the pipeline. Media flow inside the pipeline can be stopped (sealed) using various methods. In our equipment, plugging is done by inserting a plugging balloon or rubber spacer through a hole drilled in the pipeline or, if possible, disconnecting the pipeline from the face of the disconnected pipeline. In leak-free applications, the insertion of the plugging element is performed from the insertion chamber through a plugging fitting.

Temporary Pipeline Plugging Using Balloons:

Ballooning equipments RVB 2010-F1 (For pipeline inner diameters 65-300 mm, pressure up to 3 bar)

Sealing balloons for low-pressure pipelines UBF-N-MAX

Equipment UDP-F1 (For pipeline inner diameters 20-80 mm, pressure up to 0,6 bar)

Temporary Pipeline Plugging Using Rubber Spacers:

Equipment RUP-F2 (For pipeline inner diameters 11-50 mm, pressure up to 5 bar)

Equipment D-F1 (For pipeline inner diameters 32-80 mm, presure up to 0,03 bar )

Equipment COMPACT-F1/Stopl (For pipeline inner diameters 20-50 mm, pressure up to 8 bar)

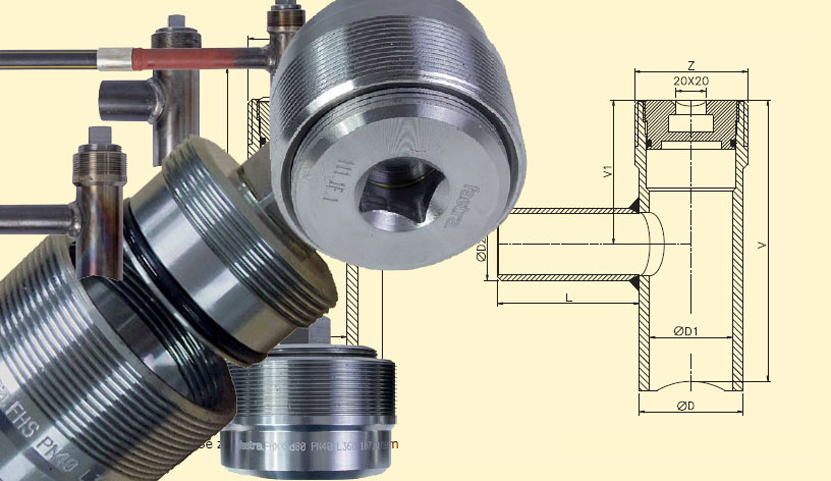

Mechanical sealings

Temporary Pipeline Plugging Using the STOPL Device

Equipment STOPL-T-F1 (For DN65-DN150 pipes with an internal overpressure of up to 10 bar)

Equipment STOPL-S-F1 (For DN65-DN400 steel pipes with an internal overpressure of up to 8 bar)

Equipment STOPL-S-F1 (For PE d90-d400 pipes with an internal overpressure of up to 8 bar)

Equipment STOPL-S-F1 DN500 (For DN500 steel pipes with an internal overpressure of up to 8 bar)

Equipment STOPL-S2-F1 (For DN200-DN500 steel pipes with an internal overpressure of up to 16 bar)

Equipment STOPL-S2-F1 (For PE d225-d400 pipes with an internal overpressure of up to 16 bar)

Equipment STOPL-S4-F1 (For DN80-DN500 steel pipes with an internal overpressure of 0-40 bar)