A Pipe Cut That Demanded More Than Just Technique – A Story from Liberec

As part of the project konecpary.cz, we took part in the dismantling of an above-ground DN500 gas pipeline in Liberec. It was a pipe bridge being removed to make way for a new underground route. What first seemed like a routine operation soon turned into a real technical challenge.

A pipe full of surprises

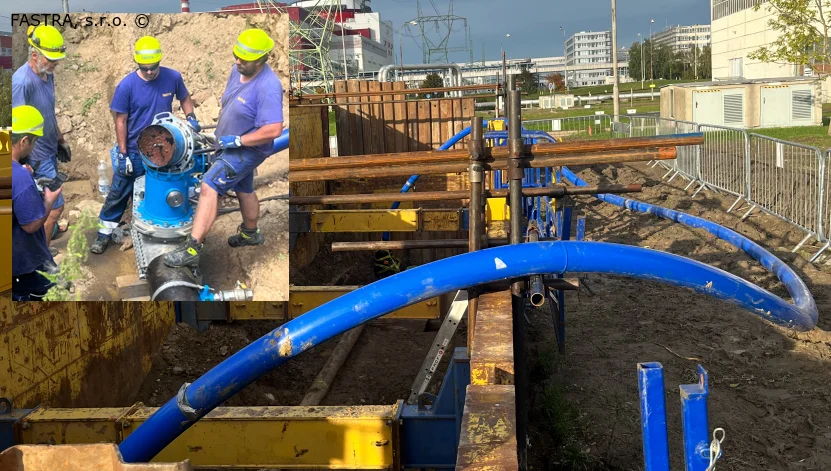

An atypical pipe segment – a historical bend with a ribbed surface. This unusual texture at the bend made it difficult to secure the cutting equipment. In practice, this meant one thing: standard procedures were not enough – improvisation was necessary.

It took both technology and human skill

We solved the situation using our PHP 300 hydraulic saw, equipped with a specially extended blade. But this intervention was not just about technology – the key role was played by our experienced installation specialists. Thanks to their ingenuity, skill, and ability to respond quickly in unusual situations, the obstacle was overcome without unnecessary delays.

Safe even in explosive environments

The PHP 300 hydraulic saw is designed to be completely free of light metal alloys. This makes it safe to use even in potentially explosive environments – such as gas pipelines. Work could continue without further safety-related delays.

Time was of the essence

The entire operation took place during a planned short shutdown of the gas-steam boilers. Our technicians had to work with maximum precision and coordination to avoid jeopardizing the schedule of follow-up work. And they succeeded – safely, quickly, and in full compliance with strict standards.

Summary: Why was this an exceptional intervention?

Atypical historical pipe prevented normal equipment attachment.

The situation was solved using the PHP 300 saw with a special blade and professional installation team.

Safety ensured thanks to the saw’s non-ferrous design.

Expertise and improvisation of our technicians were key.

The work was completed during a short shutdown with no delay.

An experience that proves the value of being prepared

The Liberec project once again confirmed the importance of being able to respond to unexpected situations with both technical confidence and human judgement. The combination of high-quality equipment and team expertise played a key role. Even a seemingly routine operation can hide technical challenges – which is why we emphasize flexibility, precision, and safety at every stage of the work.