Hydraulic Compression of PE Pipes d225 and d315 in Nymburk

Compression of polyethylene (PE) pipes is rarely used in practice, both for small and especially for larger dimensions. Smaller sizes can be handled with portable or small hydraulic compressors, but for larger dimensions such as d225 and d315, this method is practically not applied. The reason lies in the demanding requirements for trench lengths, which are particularly difficult to achieve in urban areas. Therefore, this technology is used only exceptionally.

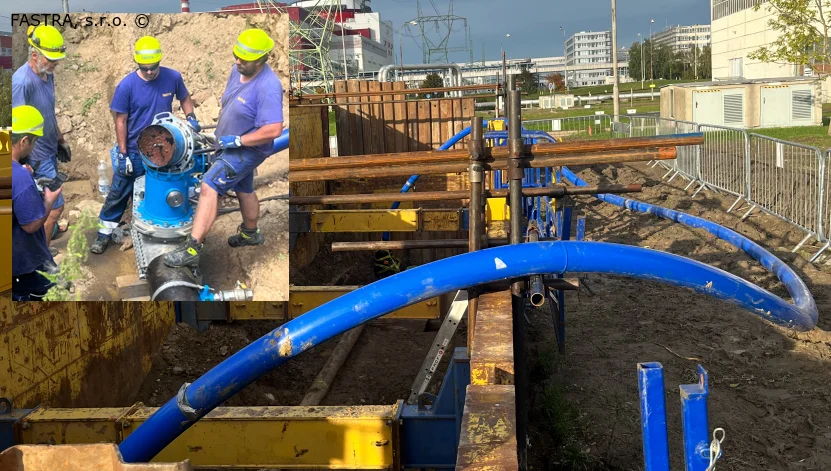

When we received an order for pipe compression in Nymburk, it was a unique opportunity for us. We could once again deploy our Hydraulic Compression Device STOP225315, which we developed and manufactured several years ago in cooperation with GasNet.

Advantages of pipe compression

The main advantage of pipe compression is its speed of installation. Compression avoids the need for welding stop fittings, which significantly accelerates the process. This is especially important in case of pipeline failures, when every minute matters and quick restoration of the pipeline network is crucial.

Professional interest

Due to its unusual character, this project attracted considerable interest from professionals. Several specialists came to the site to see how our device would perform after some time and in such a specific task. The STOP225315 device proved to be highly reliable and efficient once again.

Summary

Hydraulic compression of larger PE pipe dimensions is a technology that is rarely applied, but in certain situations it can bring significant time savings and efficiency. The deployment of our STOP225315 device in Nymburk demonstrated that even less frequently used methods can play a key role in practice.