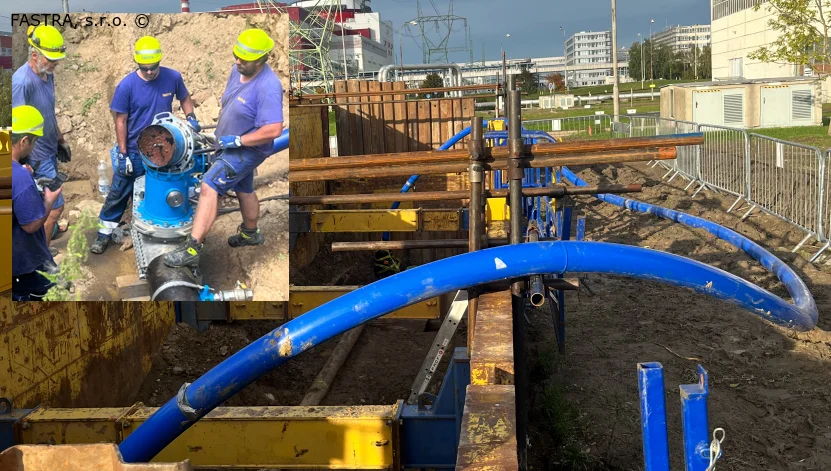

Stoppling of a Medium-Pressure Gas Pipeline DN 250 in Germany

At the end of 2025, FASTRA participated in a technologically demanding project involving a medium-pressure gas pipeline DN 250 in Germany. The project included the modernization of the pipeline at an operating pressure of 3 bar, preparing the infrastructure for new connections and ensuring long-term reliability of the network.

Project Context

The original installation used inappropriate technologies and fittings that did not meet technical or safety standards. FASTRA was brought in to implement a compliant and safe solution. The main objectives included:

- Safe stoppling of the DN 250 medium-pressure gas pipeline

- Ensuring uninterrupted gas supply during the works

- Installation of branches with transition from steel to plastic piping

- Compliance with all technical, operational, and safety requirements

Implementation Process

- Safe stoppling and bypass setup

The DN 250 pipeline was stoppled from both sides, and a bypass was installed to maintain uninterrupted gas supply, minimizing operational risks. - Installation of branches with transition from steel to plastic

Sections of the pipeline that did not meet technical requirements were removed, and new branches with a transition from steel to plastic piping were installed, fully meeting technical and safety standards. This upgrade prepared the pipeline for further technological connections. - Inspection and commissioning

Final tests were conducted for tightness, functionality, and safety. The pipeline was returned to operation without any interruption in gas supply.

Project Benefits

The project demonstrates FASTRA’s ability to handle technologically complex interventions on medium-pressure gas pipelines. Stoppling DN 250, installing steel-to-plastic branches, and maintaining continuous gas supply confirm our expertise in delivering safe, high-quality solutions. Proper technology selection and precise execution are essential for long-term pipeline reliability, even in an international context.