No shutdowns, no reductions: New FASTRA fitting for full-bore branching on same-size PE pipelines

At the beginning of 2025, FASTRA introduced to the market an innovative electrofusion fitting – the HTT EFS2 – which allows a full-bore branch connection on PE pipelines of the same dimension as the main line, for example, d110 to d110.

In recent years, FASTRA has been expanding its range of tapping saddles to new dimensions and pressure classes. The new HTT EFS2 product represents a significant step forward by enabling full-bore branching on PE pipelines without the need for dimension reduction.

The electrofusion fitting is suitable for tapping PE pipelines under pressure with natural gas, water, and other media. Available dimensions will gradually range from d90 up to d400, covering the common sizes used in the Czech Republic.

The system is designed to require no auxiliary welding or pressing equipment, which greatly simplifies and speeds up installation. The branch connection to the valve can be made either by butt welding or electrofusion coupling.

“This innovation allows full-bore branches on PE pipelines where previously it was necessary to shut down the pipeline, cut it out, and insert a T-piece. Our solution enables branching without shutdowns, with minimal excavation and surface disturbance. We want to push the market possibilities again and show that nothing is impossible,” says Miroslav Stehlík, Managing Director of FASTRA.

The HTT EFS2 builds on FASTRA’s long-term experience with electrofusion fittings and tapping saddles for PE pipelines, of which there are already several hundred in the market.

The new product’s use is not limited to gas pipelines but also extends possibilities for water pipelines and other media, reflecting FASTRA’s development beyond the gas industry.

“The introduction of this product expands the options for full-bore tapping, which we previously mainly offered for steel pipelines, to modern polyethylene systems,” adds Mr. Stehlík.

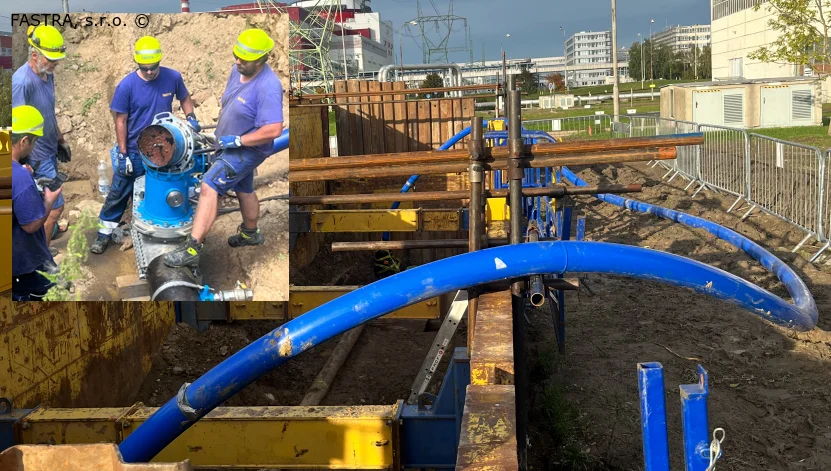

The attached photos show the first installation of the HTT EFS2 electrofusion fitting in Jeseník. This project was selected due to recent floods when the main line was newly constructed. The pipeline operator chose this innovative method so that after a short period of operation, no compression or ballooning would be required, which could damage the new pipeline.

For more information, please contact our sales department:

https://fastra.info/contacts.html