Challenging VTL Stoppling Operation near Frýdek-Místek

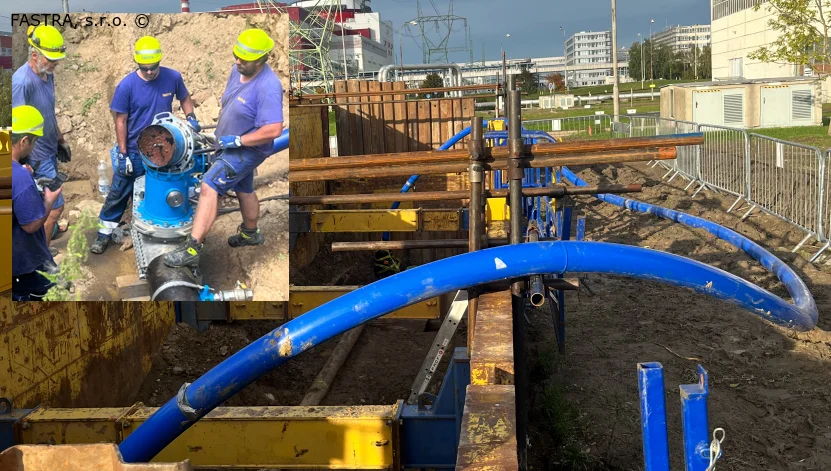

Our latest project took us to a location that tested both the technical and organisational abilities of our team. We carried out double-sided VTL stoppling DN200 and single-sided VTL stoppling DN100 with maximum DN100 bypasses. The medium was natural gas, and the demanding environment was evident from the very beginning.

The location involved an extensive excavation, very wet subsoil with a large amount of mud, and low night temperatures below freezing. Daytime warming was mild, but sufficient to allow work in the field. In addition, it was necessary to remove an old terrace valve, install a new one, and perform a number of welding operations requiring precise procedures and coordination.

Terrain challenges and preparation of the intervention

Working in such an environment was not only physically demanding. Mud and a waterlogged excavation posed a risk of slipping and complicated the handling of heavy equipment. Low temperatures also affected the stability of work surfaces and slowed down the execution of individual operations.

Every step was carefully planned. The team had to ensure the safe isolation of the pipeline and the installation of the plug with regard to the high medium pressure and the complex pipeline configuration. The combination of stoppling dimensions DN200 and DN100 together with maximum DN100 bypasses required precise technical settings and coordination to ensure a smooth intervention.

Course of the intervention

The work extended over several days. The team worked in the excavation on Tuesday and Wednesday until late at night, and the installation of the plug continued the following morning. Every operation — from removing the old valve to the welding works — was demanding both technically and logistically.

The professionalism and experience of our team were essential. Precise planning, strict adherence to safety procedures, and the ability to work under demanding conditions enabled the successful completion of the project.

Result and evaluation

The intervention was completed without complications, and the pipeline system was safely and fully sealed. The combination of challenging conditions, extensive excavation, and numerous operations highlighted the team’s professional preparedness and ability to handle even complex and atypical situations.

This project proves that every assignment has its specific demands — and that an experienced team can handle situations where others might give up or refuse to even start. Professionalism, diligence, and expertise are values we are proud of and bring to every project.