Hydrogen testing on FASTRA products

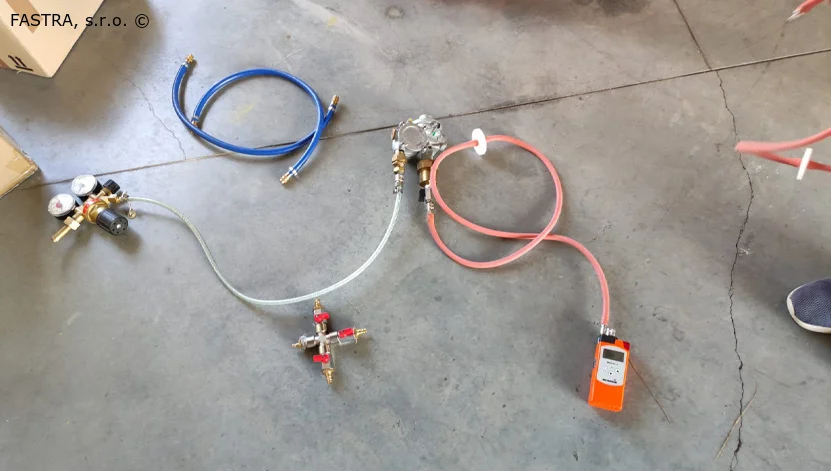

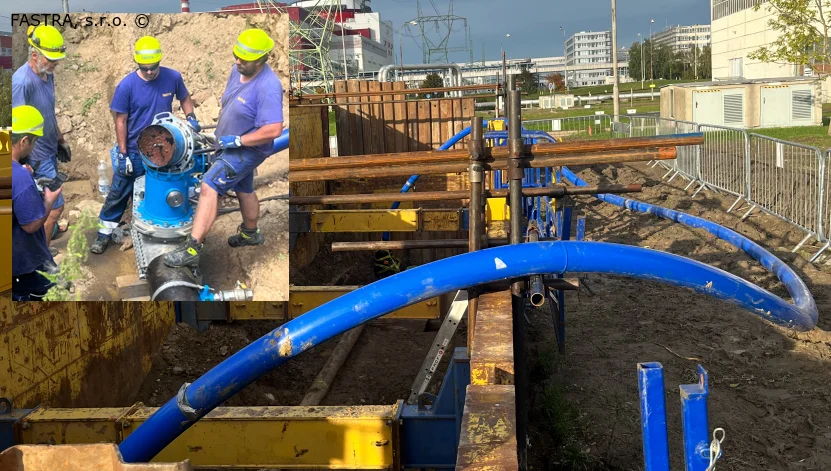

In September, tests were carried out at our site on our equipment designed to shut off special gas pipelines. The tests were carried out with several types of gases. The first basic gas was ordinary natural gas, represented by pure methane. The next level was using a mixture of natural gas with 20% hydrogen. The last gas tested was 100% hydrogen.

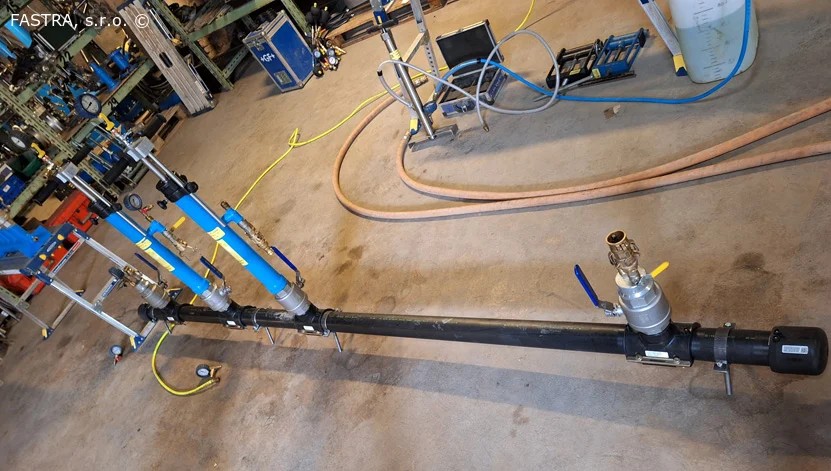

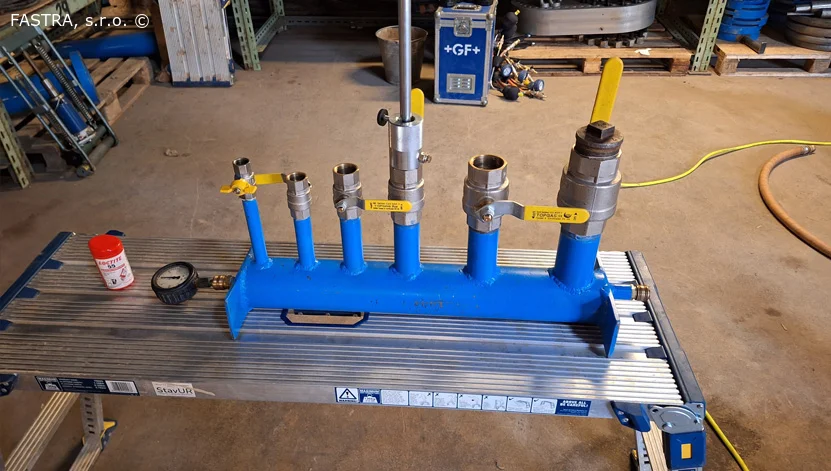

The technologies we test were manually inserted UBF-N-MAX balloons, followed by RVB 2010 – F1 balloon sets, the STOPL-S-F1 line stopping set, compressors, and then finally the RUP-F2 set, which was also tested separately, on a separate mill-sealed PE pipe with a diameter of d90.

Representatives of the gas companies GasNet Služby, Pražská plynárenská and EG.D. under the auspices of the Czech Gas Association (CGA), working group no. 10, were present during the tests.

The sealing methods tested met and exceeded everyone's expectations, especially when 100% hydrogen was used.

We will bring you more detailed results after the results of the CGA working group have been published.

However, we can already tell that the results were perfect, not only for the line stopping technology, and there were no leaks, not even of pure hydrogen.

We would like to thank everyone involved for the opportunity to carry out these tests